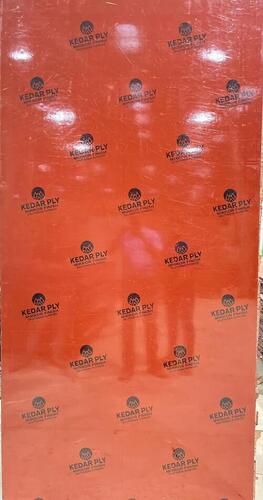

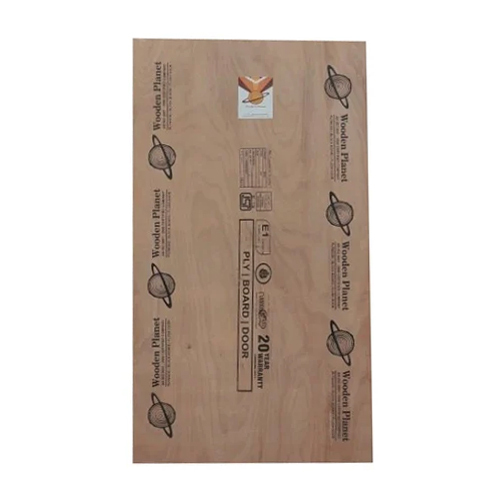

Waterproof Film Faced Shuttering Plywood

Product Details:

- Core Material Harwood

- Formaldehyde Emission Standards E1

- Usage Packing, construction, Flooring, Shipping Containers, Outdoor

- Grade Special Class

- Material Harwood

- Thickness 12, 16, 18 Millimeter (mm)

- Glue E1

- Click to View more

Waterproof Film Faced Shuttering Plywood Price And Quantity

- 62 INR/Square Foot

- 10000 Square Foot

Waterproof Film Faced Shuttering Plywood Product Specifications

- Harwood

- Harwood

- 12, 16, 18 Millimeter (mm)

- E1

- E1

- Packing, construction, Flooring, Shipping Containers, Outdoor

- Special Class

Waterproof Film Faced Shuttering Plywood Trade Information

- Letter of Credit (L/C)

- 5000 Square Foot Per Month

- 10 Days

- Yes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- BIS, FSC

Product Description

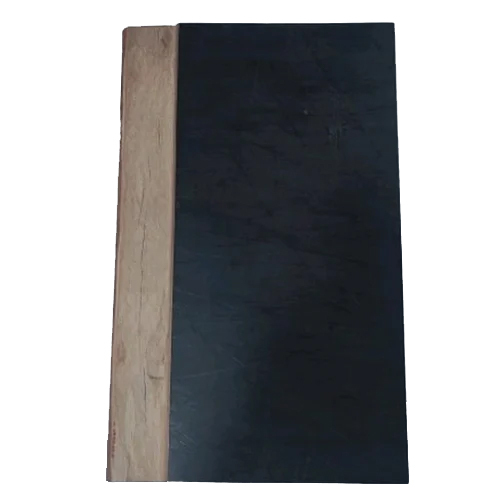

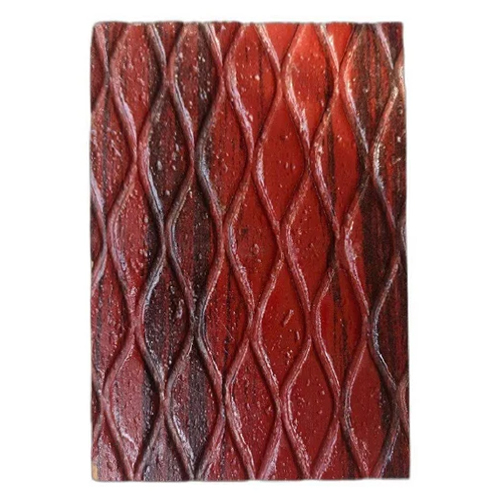

Mirror Finish Waterproof Film Faced Shuttering Plywood, which is designed for the use in construction projects, particularly to create formwork or temporary structures. It features a thickness of 12mm and is thoroughly coated with a long-lasing film on both sides, normally made of phenolic resin. This film offers superb protection against abrasion, chemicals, and moisture. It is constructed utilizing chosen grade hardwood veneers, which are perfectly bonded with waterproof adhesives, to guarantee structural strength and stability. 12mm Film Faced Shuttering Plywood is known for its convenient demolding, re-usability, and smooth surface finish, making it the best option for a number of concrete construction applications.

Superior Durability for Outdoor Use

Designed specifically for outdoor conditions, this plywood features a waterproof film facing that resists moisture and extends lifespan. The robust hardwood core and special class grading guarantee structural integrity, making it a reliable choice for construction sites, shipping containers, and heavy-duty flooring.

Compliance with E1 Formaldehyde Emission Standards

Safety is prioritized through the use of E1 grade glue, which restricts formaldehyde emissions within international limits. This feature ensures a healthier environment for workers and users, especially in enclosed or high-traffic areas where indoor air quality is essential.

FAQs of Waterproof Film Faced Shuttering Plywood:

Q: How is waterproof film faced shuttering plywood manufactured to withstand outdoor conditions?

A: This plywood is crafted using hardwood core material and coated with a waterproof film on both sides. It is then bonded with E1-grade glue, making it highly resistant to water, humidity, and harsh weather, which is essential for outdoor construction and flooring.Q: What are the main applications of this plywood in construction and shipping industries?

A: Its primarily used in formwork for concrete, scaffold planking, container flooring, and outdoor staging. Its robust structure and weatherproof qualities make it ideal for repeated use in shipping containers, site floors, and exposed scaffolds.Q: When should I choose this plywood thickness for my project?

A: Select 12, 16, or 18 mm thickness based on the load requirements and application. Thicker boards (16 or 18 mm) are recommended for heavy-duty flooring and container construction, while 12 mm suits lighter formwork or paneling needs.Q: Where can I purchase waterproof film faced shuttering plywood in India?

A: It is available through a wide networkincluding dealers, distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalersacross India. You can contact local authoritative distributors for supply and delivery options.Q: What is the benefit of E1 formaldehyde emission standard in this plywood?

A: E1 formaldehyde emission standard ensures that the plywood releases very low levels of formaldehyde, supporting safe air quality during usage and storage. Its especially beneficial in enclosed areas or during prolonged exposure.Q: How is this plywood packed and shipped to ensure it arrives undamaged?

A: The plywood is typically stacked on pallets, wrapped, and sometimes banded with protective material to avoid moisture ingress and physical damage during transport. This method ensures the panels retain their quality from manufacturer to user.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese